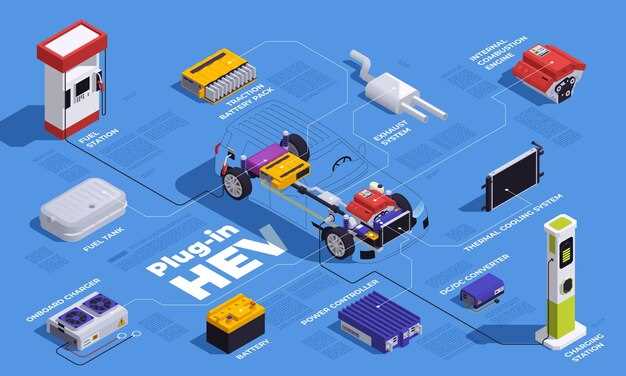

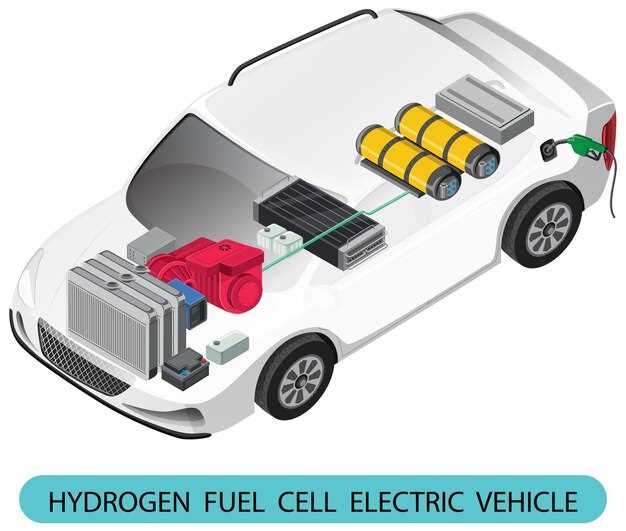

When it comes to powering vehicles and machinery, electric motors and internal combustion engines (ICE) are two distinct technologies that exemplify different approaches to energy conversion. Understanding the fundamental differences between these two systems is crucial for both consumers and engineers, as each offers unique advantages and challenges.

Electric motors operate by converting electrical energy into mechanical energy, utilizing electromagnetic principles. This method allows for high efficiency and instant torque delivery, making them ideal for applications such as electric vehicles and industrial equipment. In contrast, combustion engines rely on the chemical energy stored in fossil fuels, which is converted into mechanical energy through a series of controlled explosions within the engine’s cylinders. This process is inherently less efficient, leading to a variety of performance and environmental considerations.

Another significant difference lies in maintenance and operational costs. Electric motors generally require less maintenance due to fewer moving parts and the absence of traditional fuels. In contrast, ICEs demand regular servicing to ensure optimal performance and longevity, which translates to higher costs over time. Additionally, the environmental impact of these technologies is starkly different; electric motors produce zero emissions at the point of use, while combustion engines contribute significantly to air pollution and greenhouse gas emissions.

In analyzing these distinctions, it becomes evident that the choice between electric motors and combustion engines is not merely a question of power, but also of efficiency, maintenance, and environmental responsibility. Each technology plays a pivotal role in the ongoing evolution of transportation and energy, shaping the future of how we power our world.

Comparison of Power Output in ICE Engines and EV Motors

When discussing the power output of internal combustion engine (ICE) vehicles versus electric vehicles (EVs), several factors come into play. Both systems generate power differently, resulting in distinct performance characteristics.

Power Characteristics

- Instant Torque in EVs: Electric motors deliver maximum torque instantly from a standstill. This characteristic allows EVs to accelerate rapidly and offers a responsive driving experience.

- Power Band in ICE: Combustion engines typically operate efficiently within a specific RPM range. Their power output is often characterized by a peak torque that occurs at higher RPMs, which can affect acceleration in lower speed scenarios.

Power Output Measurement

- Horsepower and Torque: ICE are commonly rated in horsepower and torque. Horsepower indicates the engine’s ability to perform work over time, while torque measures the engine’s rotational force.

- Continuous Power in EVs: EV motors are measured by kilowatts (kW). This metric highlights the continuous power output capability, which is crucial for maintaining consistent performance.

Efficiency Considerations

- Energy Conversion: EV motors convert more than 90% of electrical energy from the battery into usable power, while ICE typically convert only about 20-30% of fuel energy into mechanical power.

- Heat Loss in ICE: Combustion engines generate significant heat energy as a byproduct, further reducing overall efficiency and power output potential.

Practical Implications

Understanding the differences in power output between ICE engines and EV motors is essential for consumers and engineers alike. While EVs provide immediate and sustained power, ICE engines offer different power delivery characteristics suitable for traditional automobile applications. The choice between an electric motor and a combustion engine ultimately depends on the intended use, performance requirements, and personal preferences.

Maintenance Requirements: ICE Versus Electric Motors

Internal Combustion Engines (ICE) require regular maintenance to ensure optimal performance and longevity. This includes frequent oil changes, air filter replacements, and spark plug inspections. Additionally, cooling systems must be monitored, and the fuel system periodically cleaned to prevent clogs. Engine belts and hoses are also subject to wear and need replacement at specific intervals.

In contrast, Electric Vehicles (EV) with electric motors demand significantly less maintenance. The absence of moving parts like pistons, valves, and fuel systems means fewer components that can fail or require replacement. EV maintenance typically involves routine checks of the battery system and software updates. Tire rotation and brake inspections also remain important, but the overall maintenance frequency is considerably lower than that of ICEs.

The overall cost of maintaining ICEs is generally higher due to the complexity and number of components that need attention. Conversely, electric motors provide a cost-effective maintenance approach, appealing to environmentally conscious consumers. As technology advances, the simplicity of EV maintenance is likely to attract even more users.

Fueling Infrastructure: Challenges for ICE Engines and EVs

The fueling infrastructure serves as a critical backbone for both internal combustion engine (ICE) vehicles and electric vehicles (EVs), yet the challenges faced by each differ significantly. For ICE vehicles, the established network of gas stations provides a relatively straightforward refueling process. However, this reliance on fossil fuels presents challenges such as fluctuating fuel prices, environmental concerns, and the need for continuous drilling and refining activities.

In contrast, EVs encounter unique obstacles related to their charging infrastructure. While the number of charging stations is on the rise, there remains a significant disparity in availability, especially in rural areas. The time required to charge an EV is also a concern; traditional ICE motors can be refueled in mere minutes, whereas charging an EV can take anywhere from 30 minutes at a fast charger to several hours at a standard outlet.

Moreover, the grid capacity to handle a surge in EV charging, especially during peak hours, raises questions about the sustainability of this infrastructure. It requires substantial investments in upgrading power materials and installations to accommodate increased demand.

Finally, user convenience plays a crucial role for both types of vehicles. While ICE drivers are accustomed to a well-established refueling process, EV users are still adapting to planning longer trips around charging opportunities. This necessity creates a potential barrier to broader EV adoption, particularly in markets with limited charging infrastructure.

In conclusion, the challenges posed by fueling infrastructure for ICE engines and EVs reveal the distinct hurdles each technology must overcome to thrive in the evolving automotive landscape.